Plc Artificial Intelligence: Advancements and Applications

PLC Artificial Intelligence (AI) is a technology that enables Programmable Logic Controllers (PLCs) to learn and adapt to new situations and data. AI technology is used to analyze sensor data and modify control settings automatically to enhance the process. The integration of AI technology with PLCs can lead to greater safety, cheaper costs, and increased production.

AI and Machine Learning (ML) algorithms are widely used in PLC-based process control systems for controlling robots. AI systems are designed to mimic human intelligence and decision-making processes, allowing them to learn from data and adapt to new situations.

One way in which AI is used in PLCs is through predictive maintenance. Predictive maintenance is the practice of monitoring equipment and systems to identify potential problems before they occur. By analyzing sensor data, AI algorithms can predict when equipment is likely to fail and alert maintenance teams to take proactive measures. This can help to prevent costly downtime, reduce maintenance costs, and extend the life of equipment.

Another application of AI in PLCs is machine vision for automatic inspection and analysis. Machine vision systems use cameras and image processing algorithms to inspect and analyze products and materials. By using AI algorithms, machine vision systems can learn to recognize defects and anomalies, and alert operators to take corrective action.

Virtual sensors are another application of AI in PLCs. Virtual sensors use AI algorithms to predict the behavior of systems and equipment based on sensor data. By analyzing historical data, virtual sensors can predict the future behavior of systems and equipment, allowing operators to take proactive measures to prevent problems.

In summary, AI technology is transforming the way PLCs are used in process control systems. By enabling PLCs to learn and adapt to new situations and data, AI technology is improving safety, reducing costs, and increasing production.

Evolution of PLC Artificial Intelligence

PLC Artificial Intelligence has come a long way since its inception in the early 1960s. Over the years, it has evolved to become a powerful tool that enables machines to think and act like humans. In the past few years, AI has garnered focus from tech companies around the world and is considered as the next significant technological shift after the evolution in mobile and cloud platforms.

The following are some of the key milestones in the evolution of PLC Artificial Intelligence:

- 1960s: The conceptual design of AI was first developed in the early 1960s. At that time, AI was mostly focused on rule-based systems, which could perform simple tasks based on pre-defined rules.

- 1980s: In the 1980s, AI started to move towards more complex systems, such as expert systems and neural networks. These systems were designed to learn from experience and improve their performance over time.

- 1990s: In the 1990s, AI started to become more practical and was used in a variety of applications, such as speech recognition and natural language processing. At this time, AI was mostly focused on narrow applications, rather than general intelligence.

- 2000s: In the 2000s, AI started to become more mainstream, with the development of machine learning algorithms and the availability of large datasets. This led to breakthroughs in areas such as image recognition and language translation.

- 2010s: In the 2010s, AI started to become more integrated into everyday life, with the rise of virtual assistants and smart home devices. At the same time, AI also started to raise concerns about its impact on jobs and privacy.

- 2020s: In the 2020s, AI is expected to continue to evolve, with the development of more advanced algorithms and the integration of AI into more industries. At the same time, there will also be a focus on addressing the ethical and social implications of AI.

Overall, the evolution of PLC Artificial Intelligence has been driven by advances in computing power, data availability, and algorithmic innovation. As AI continues to evolve, it has the potential to transform industries and improve our lives in countless ways.

Components of Plc Artificial Intelligence

When it comes to PLC artificial intelligence, there are a few key components that work together to make it all possible. These components are sensors and actuators, communication networks, and data processing.

Sensors and Actuators

Sensors and actuators are crucial components of any PLC system, including those that incorporate artificial intelligence. Sensors are used to detect changes in the environment, such as temperature, pressure, or humidity, and send that information to the PLC. Actuators, on the other hand, are used to make changes in the environment, such as turning on a motor or opening a valve.

In PLC artificial intelligence, sensors and actuators are used to collect data and make decisions based on that data. For example, a sensor might detect a drop in temperature, which could trigger an actuator to turn on a heater. This process can be automated and optimized using artificial intelligence algorithms, allowing the system to make decisions more quickly and accurately than a human operator.

Communication Networks

Communication networks are another important component of PLC artificial intelligence. These networks allow different parts of the system to communicate with each other, exchanging data and instructions as needed.

In PLC artificial intelligence, communication networks are used to connect sensors, actuators, and other components to the central processing unit (CPU). This allows the CPU to receive data from multiple sources and make decisions based on that data. Communication networks can also be used to connect multiple PLC systems together, allowing for more complex and distributed control systems.

Data Processing

Data processing is the third key component of PLC artificial intelligence. This involves taking the data collected by sensors and other components and analyzing it to make decisions.

In PLC artificial intelligence, data processing can involve a variety of techniques, including machine learning, deep learning, and other artificial intelligence algorithms. These algorithms can analyze large amounts of data quickly and make decisions based on that data. This allows the system to optimize performance, reduce downtime, and improve overall efficiency.

Overall, the combination of sensors and actuators, communication networks, and data processing is what makes PLC artificial intelligence possible. By working together, these components allow the system to collect data, make decisions, and optimize performance in real-time.

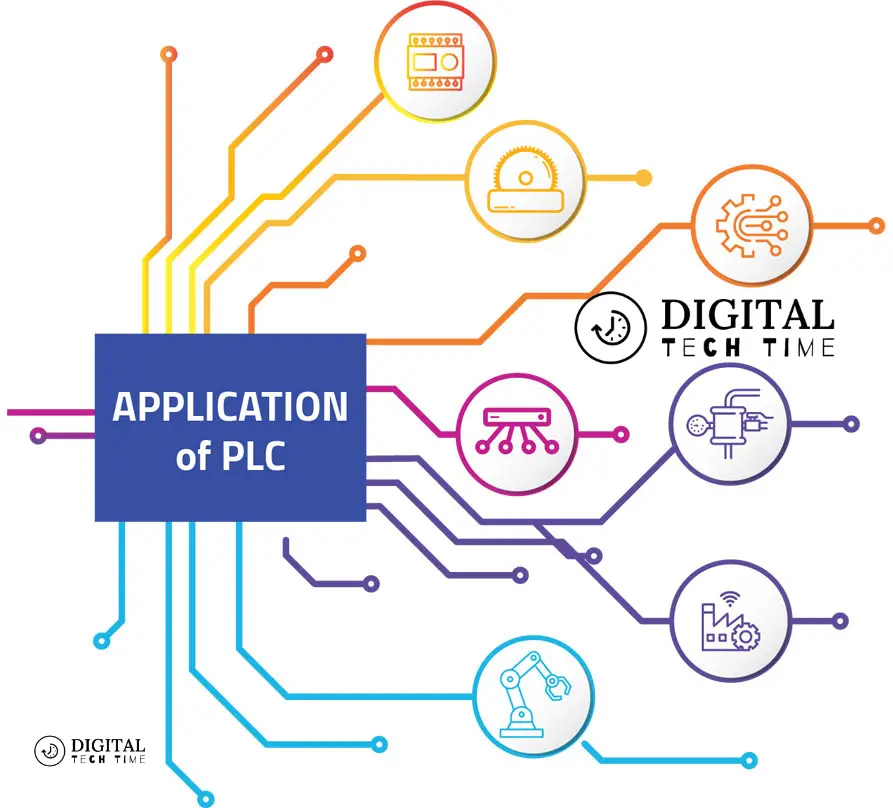

Applications of Plc Artificial Intelligence

Plc Artificial Intelligence (AI) has a wide range of applications in various industries. Here are some of the most common applications:

Manufacturing

Plc AI is widely used in the manufacturing industry to automate production processes. It can be used to control various equipment and machines on production lines, such as handling robots, machine tools, conveyor belts, machining centers, and more. Plc AI can help improve efficiency, reduce downtime, and increase productivity. By analyzing data and making predictions, Plc AI can also help prevent equipment failures and reduce maintenance costs.

Energy Management

Plc AI is used to optimize energy consumption in buildings and factories. By analyzing data from sensors and other sources, Plc AI can identify areas where energy is being wasted and suggest ways to reduce consumption. It can also predict energy demand and adjust energy usage accordingly. Plc AI can help reduce energy costs, increase energy efficiency, and reduce carbon emissions.

Transportation

Plc AI is used in transportation systems to improve safety, efficiency, and reliability. It can be used to control traffic signals, monitor traffic flow, and optimize routes for vehicles. Plc AI can also be used to predict maintenance needs for vehicles and reduce downtime. It can help reduce traffic congestion, improve fuel efficiency, and reduce accidents.

In conclusion, Plc AI has a wide range of applications in various industries. It can help improve efficiency, reduce costs, and increase productivity. By analyzing data and making predictions, Plc AI can also help prevent equipment failures and reduce maintenance costs.

Challenges in PLC Artificial Intelligence

When it comes to implementing artificial intelligence (AI) in programmable logic controllers (PLCs), there are several challenges that you might face. In this section, we will discuss some of the common challenges that you might encounter.

Data Security

One of the major challenges in PLC AI is data security. PLCs are often used in industrial settings where data privacy and security are of utmost importance. If the data is not secured properly, it can lead to serious consequences such as loss of sensitive information, damage to equipment, and even physical harm to employees. Therefore, it is important to ensure that the data is encrypted and secured using appropriate security measures.

Interoperability

Another challenge in PLC AI is interoperability. PLCs are often used in conjunction with other systems such as sensors, robots, and other control systems. Therefore, it is important to ensure that the AI system is compatible with these systems. This can be a challenging task, as different systems may use different protocols and communication methods. To overcome this challenge, it is important to ensure that the AI system is designed to work with a wide range of systems and protocols.

Scalability

Scalability is another challenge in PLC AI. As the amount of data generated by the system increases, it can become difficult to process and analyze the data in real-time. This can lead to delays in decision-making and can impact the overall performance of the system. To overcome this challenge, it is important to design the AI system to be scalable and to use appropriate hardware and software to handle large amounts of data.

In conclusion, implementing AI in PLCs can be a challenging task. However, by addressing the challenges of data security, interoperability, and scalability, you can ensure that your AI system is effective and efficient.

Future of PLC Artificial Intelligence

PLC Artificial Intelligence (AI) is a rapidly evolving field that is expected to bring about significant changes in the manufacturing industry. As technology advances, PLC AI is becoming more sophisticated, with the ability to handle complex tasks and make intelligent decisions.

Increased Efficiency

One of the key benefits of PLC AI is increased efficiency. By automating tasks, PLC AI can reduce the time and effort required to complete them, allowing manufacturers to produce more goods in less time. Additionally, PLC AI can analyze data in real-time, identifying patterns and anomalies that could indicate a problem with the manufacturing process. This allows manufacturers to identify and address issues quickly, reducing downtime and minimizing the impact on production.

Improved Safety

PLC AI can also help to improve safety in the manufacturing industry. By automating hazardous tasks, such as working with chemicals or heavy machinery, PLC AI can reduce the risk of injury to workers. Additionally, PLC AI can monitor the manufacturing process, identifying potential safety hazards and alerting workers to take action.

Integration with Other Technologies

As PLC AI continues to evolve, it is expected to become increasingly integrated with other technologies, such as the Internet of Things (IoT) and big data analytics. This integration will allow PLC AI to access and analyze vast amounts of data, providing manufacturers with insights into their operations that were previously impossible to obtain.

Challenges and Limitations

Despite the many benefits of PLC AI, there are also challenges and limitations that must be addressed. One of the biggest challenges is the need for skilled workers who can design, implement, and maintain PLC AI systems. Additionally, there are concerns about the impact of PLC AI on employment, with some experts predicting that it could lead to job losses in certain industries.

Another limitation of PLC AI is its reliance on data. In order to make intelligent decisions, PLC AI requires access to accurate and reliable data. If the data is incomplete or inaccurate, the decisions made by PLC AI may be flawed, leading to errors in the manufacturing process.

Conclusion

Overall, the future of PLC AI is bright, with the potential to revolutionize the manufacturing industry. While there are challenges and limitations that must be addressed, the benefits of PLC AI are clear, and it is expected to play an increasingly important role in the years to come.

Frequently Asked Questions

What is the relationship between PLC and AI?

PLC or Programmable Logic Controller is a device used for automation in industries. AI or Artificial Intelligence is a technology that enables machines to learn and make decisions like humans. The relationship between PLC and AI is that AI can be used to enhance the capabilities of PLC systems. AI can help PLC systems to learn from data and make better decisions.

Can machine learning be applied to PLC programming?

Yes, machine learning can be applied to PLC programming. Machine learning algorithms can be used to analyze data from PLC systems and learn from it. This can help to optimize the performance of PLC systems and improve their efficiency.

How can AI improve PLC programming?

AI can improve PLC programming in several ways. It can help to optimize the performance of PLC systems by analyzing data and making predictions. It can also help to identify anomalies in the data and alert operators to potential issues before they become critical. AI can also enable PLC systems to learn from data and make better decisions, which can improve their efficiency and reduce downtime.

What are the benefits of combining PLC and AI?

The benefits of combining PLC and AI include improved efficiency, reduced downtime, and better decision-making. AI can help to optimize the performance of PLC systems and identify potential issues before they become critical. This can reduce downtime and improve the overall efficiency of the system. AI can also enable PLC systems to learn from data and make better decisions, which can improve their performance and reduce the need for human intervention.

Is there a future for PLC in the age of AI?

Yes, there is a future for PLC in the age of AI. While AI can enhance the capabilities of PLC systems, it cannot replace them entirely. PLC systems are still essential for automation in industries, and their role will continue to be important in the future.

What are the limitations of using AI in PLC programming?

The limitations of using AI in PLC programming include the need for large amounts of data to train the machine learning algorithms. The quality of the data is also crucial for the accuracy of the predictions made by the system. Another limitation is the need for skilled personnel to design, implement, and maintain the system. Finally, the cost of implementing AI in PLC systems can be significant, which may limit its adoption in some industries.

More information read Programmable logic controller